Over the last 20 years, Adept Civil Group has built a reputation as one of the most reliable water authority accredited contractors in Melbourne. With the demand for water, sewerage and drainage services increasing, Anthony Panozzo, Managing Director at Adept Civil Group , said the company made the decision two years ago to strategically expand its capabilities and better position itself to meet this opportunity head-on.

As part of the expansion, Adept Civil Group created a microtunnelling division within the company which works alongside with the civil division. It has also recently purchased a Vermeer AXIS laser guided boring machine which will be used by the new division.

“The addition of the Vermeer AXIS laser guided boring machine to our fleet not only complements our existing civil division but also provides our clients with an all-encompassing microtunnelling offering. In-house microtunnelling capabilities allow Adept Civil Group greater control over the delivery and cost of projects,” Mr Panozzo said.

“After many years of experience in subcontracting laser guided boring machines, we chose the Vermeer AXIS machine due to its reliability in varying ground conditions and pinpoint accuracy.”

Meeting the needs of a changing industry

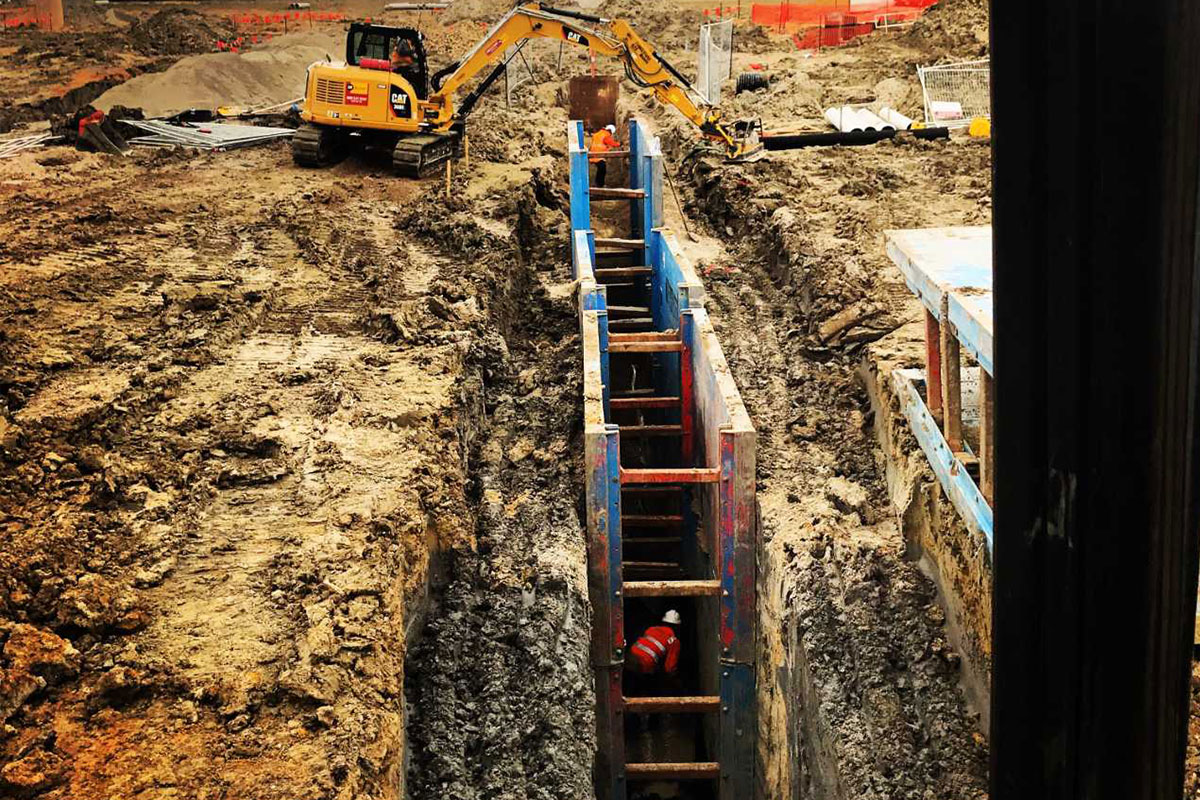

Mr Panozzo said one of the reasons the company decided to diversify was a shift in the civil construction industry which has seen the use of trenchless methods of utility installation being increasingly chosen over open cut methods where possible.

“Having been in the civil construction industry for 20 years, we have seen many changes to the way pipeline projects are constructed. Notably we have seen a purposeful shift from open cut to trenchless methods for a wide range of reasons, including pre-existing infrastructure, built up urban environments, and culturally and environmentally sensitive areas,” Mr Panozzo said.

“The AXIS machine allows for the installation of grade critical infrastructure in areas where traditional open cut methodologies are neither practical nor efficient.

“The current infrastructure boom in Victoria has created high demand for microtunnelling, and we are proud to be able to offer the growing industry and marketplace our improved capabilities, and trust that our latest addition will be greatly received.”

From the US to Australia: selecting the equipment

“Our relationship with Vermeer first started with a trip to Vermeer’s corporate head office and manufacturing facility in Pella, Iowa, where we met with representatives from the Australian dealership and the family founders of Vermeer,” Mr Panozzo said.

“Vermeer were very accommodating whilst we were in Pella; we were personally guided through the factory floors, from development to manufacturing, and met with the original developers of the AXIS machine.

“It was reassuring to find Vermeer invests heavily in research and development, ensuring they continue to be market leaders in their field. This gave our management group—Jennifer Stewart, Group General Manager; Quentin Powell,Group Operations Manager; and Brett Moore Group Microtunnelling Manger—great confidence in our choice to partner with Vermeer.”

Click here to read the full article in the September edition of Trenchless Australasia

MyDealer:

MyDealer: