In the 1970s, Gary Vermeer had a vision: if Vermeer could develop a machine that could dig in a manner similar to a mole tunnelling underneath a road, without opening up a trench, it would blow open the market, and make Vermeer an industry pioneer.

Over the next decade this vision became a reality, and the industry saw the potential impact this would have in underground construction.

The early days

Vermeer has always had a culture of innovation. In 1979, Vermeer introduced a simple rotary attachment (also known as a porta bore) that was used on small- to medium-size trenchers and vibratory plows for tunnelling underneath different rights-of-way and other obstacles. It was a simple attachment that proved to be popular, as it saved time and money by eliminating the need to open cut footpaths and driveways. After the introduction of the porta bore, Vermeer could further see the potential in underground infrastructure and trenchless technology.

Vermeer’s first HDD machines

The first trenchless machines started to make their way into the Australian market in the 1990s, and the demand for this type of technology started to rise. The time was ripe for Vermeer to start designing its own trenchless machinery and put its stamp on this revolutionary product.

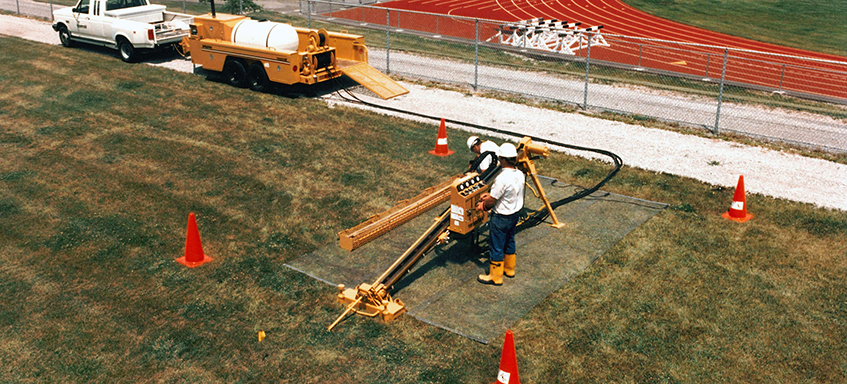

The first horizontal directional drilling (HDD) machine Vermeer introduced was the Navigator® HDD (which later became the D7 model) in 1991. It was a basic model that needed a significant amount of labour to set up and drill. Everything on these machines was a manual process.

Vermeer’s team spent a lot of time in the field staging demonstrations for customers, introducing them to this new technology and gathering on-the-ground feedback. In 1995 the second generation of self-contained HDD drills was introduced to the Australian market – this was the defining moment for Vermeer, as it put its mark on this up-and-coming industry.

Industry impact and notable projects

Product reliability has always been a big focus for Vermeer, and still is to this day. Improvements in the machine hydraulics and the introduction of a forged rod enhanced drill performance, reliability and helped build confidence in the technology.

HDDs, known for their low impact on the surrounding environment, have played an integral part in many significant construction and infrastructure projects across Australia.

In the 90s, the rollout of Foxtel and cable television to households required trenchless technology for minimal disturbance to residential areas, and Vermeer’s HDDs were often the machine of choice. The installation of NBN from 2011 saw HDDs playing an increasingly important role in connecting households to the network. The trenchless technology benefitted residents and the environment and provided economic benefits, allowing a connection to be established with as little impact as possible.

Rigs for jobs big and small

The introduction of compact Vermeer HDDs in the late 90s and early 2000s, such as the D7X11 and D16X20, allowed for more versatility when working with differing ground conditions. When Vermeer introduced a smaller drill to the range, it opened up the market and offered more variety and versatility for those working with a fleet of HDDs, particularly on larger projects.

HDD technology has become more compact over the years, but it has not been at the expense of power. Customers can use compact machines on a larger job that might have tight access, but still expect the same drilling performance and output that the larger models offer.

The S3 range

The S3 range of Vermeer HDDs was introduced in 2015 and made rock drilling a lot simpler for operators, without compromising on productivity. The range includes the smaller D10x15 S3 HDD, weighing just over 3,000kg, up to the 17,000kg D60x90 S3 HDD.

The range’s control interface, which includes the ability to load your plan onto the screen in front of you instead of referring to hard copies when mapping out where to drill, made tasks vastly easier. The S3 range is also quieter than previous models, meaning less disturbance to the surrounding environment, a real plus for residential and suburban projects.

Technology of the future

Vermeer is always looking at ways that technology can improve operations for customers, whether that’s through product improvements, research and development, or the latest training techniques.

The NavigatorTM HDD Simulator 2.0 was developed to take the headache out of HDD training, which can often be costly and time consuming. Packed with features, the Horizontal Directional Drill Simulator trains operators on the basics of operating drill controls, using real-world drilling simulation without the need to set foot on a real drill. Operators get instant feedback, alerting when drilling goes off target and guiding them back to safer alignment.

The simulator will be a gamechanger for many Vermeer Australia customers, with controls that span across the Vermeer line-up of drills that will help with a smooth transition to a real drill.

The Vermeer Australia of today

In 2015, Vermeer Australia became part of the RDO Australia Group, a subsidiary of North Dakota-based RDO Equipment. Globally, RDO Equipment is the world’s largest John Deere and Vermeer dealer group, with presence in Africa, Australia, Mexico, and Ukraine.

Today, RDO owns 100% of the Vermeer Australia business and comprises three dealer brands: RDO Equipment (John Deere Construction & Forestry equipment), Vanderfield (agricultural equipment), and Vermeer Australia (Vermeer industrial and environmental products). The size and breadth of the Australian industrial equipment network means the business can offer Vermeer Australia customers a range of product and level of customer support that is unmatched.

From telecommunications and electricity to gas, water and energy pipelines – underground infrastructure contractors continue to use Vermeer HDDs to get the job done, supported by one of the largest equipment dealership networks in Australia.

MyDealer:

MyDealer: